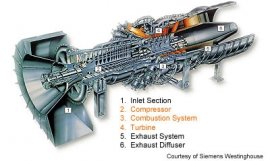

The burning (fuel) turbines being set up in lots of nowadays's natural-gas-fueled power flowers tend to be complex devices, however they basically involve three main sections:

The burning (fuel) turbines being set up in lots of nowadays's natural-gas-fueled power flowers tend to be complex devices, however they basically involve three main sections:

- The compressor, which draws air in to the engine, pressurizes it, and nourishes it toward burning chamber at rates of a huge selection of miles per hour.

- The burning system, usually contains a ring of fuel injectors that inject a stable stream of fuel into burning chambers where it blends aided by the environment. The combination is burned at temperatures of greater than 2000 degrees F. The burning produces increased heat, high-pressure gasoline stream that goes into and expands through turbine section.

- The turbine is an intricate selection of alternate stationary and rotating aerofoil-section blades. As hot combustion gas expands through the turbine, it spins the rotating blades. The rotating blades perform a dual purpose: they drive the compressor to-draw even more pressurized environment in to the combustion section, in addition they spin a generator to produce electrical energy.

Land based fuel turbines tend to be of two sorts: (1) hefty framework motors and (2) aeroderivative engines. Heavy framework motors tend to be described as lower stress ratios (typically below 20) and are usually actually large. Pressure ratio may be the proportion of this compressor discharge stress as well as the inlet atmosphere pressure. Aeroderivative engines are based on jet motors, given that name implies, and operate at high compression ratios (typically more than 30). Aeroderivative machines are usually really small and are usually of good use in which smaller energy outputs are required. As big frame turbines have actually higher power outputs, they are able to produce bigger levels of emissions, and needs to be designed to attain low emissions of pollutants, like NOx.

One secret to a turbine's fuel-to-power efficiency may be the temperature from which it operates. Greater temperatures usually indicate higher efficiencies, which, can cause cheaper procedure. Petrol streaming through an average power plant turbine is as hot as 2300 levels F, however some of the vital metals into the turbine can resist conditions just since hot as 1500 to 1700 degrees F. Therefore, environment through the compressor might-be employed for air conditioning key turbine elements, decreasing ultimate thermal performance.

The major achievements of this division of Energy's advanced turbine program was to break-through past limits on turbine temperatures, making use of a mix of revolutionary cooling technologies and higher level products. The advanced turbines that emerged through the Department's study program could actually improve turbine inlet temperatures to up to 2600 degrees F - nearly 300 degrees hotter compared to past turbines, and attain efficiencies as high as 60 %.

One other way to enhance performance should install a recuperator or heat data recovery steam generator (HRSG) to recover power from turbine's exhaust. A recuperator captures waste heat in the turbine fatigue system to preheat the compressor release atmosphere before it comes into the combustion chamber. A HRSG creates vapor by shooting temperature from the turbine fatigue. These boilers may also be known as temperature data recovery steam generators. High-pressure vapor from all of these boilers may be used to create additional electric power with steam turbines, a configuration labeled as a combined pattern.

A straightforward period gas turbine can achieve power transformation efficiencies ranging between 20 and 35 per cent. Using the higher conditions achieved when you look at the Department of Energy's turbine program, future hydrogen and syngas fired gas turbine combined pattern plants are going to attain efficiencies of 60 % or more. Whenever waste heat is captured from all of these methods for home heating or professional functions, the entire energy pattern effectiveness could approach 80 percent.